Bringing a product with embedded electronics or wireless functionality to market involves navigating the complex challenges of electromagnetic compatibility (EMC). Compliance failures can lead to costly design iterations, project delays, and potential rejection in key regulatory markets.

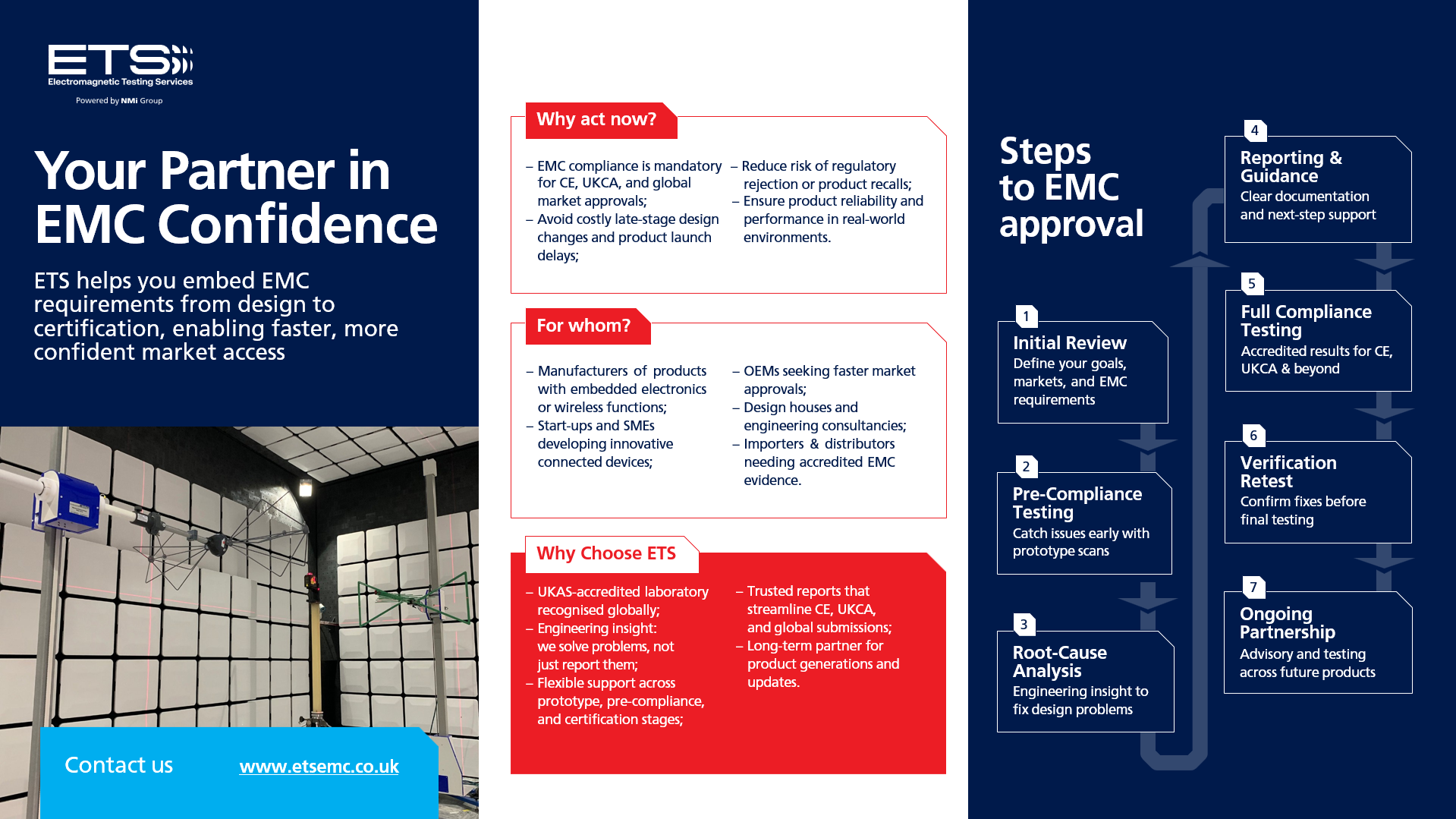

At ETS, we see EMC testing as more than a pass/fail exercise. It’s a collaborative process designed to help your product perform reliably in the real world, while meeting all the necessary standards. Here’s how our typical workflow supports you, every step of the way.

Step 1: Initial Review — Setting Goals Together

Every project begins with a conversation. We review your design goals, intended markets, and relevant EMC requirements. This scoping step ensures that the testing plan reflects the reality of your product — not a one-size-fits-all checklist.

Step 2: Pre-Compliance Testing — Catch Issues Early

Why wait until final compliance testing to discover critical issues? Pre-compliance scans in our dedicated EMC chamber provide early-stage diagnostics during the prototype phase. By detecting potential emissions or immunity vulnerabilities upfront, you can take corrective action early, reducing development risk, saving time, and avoiding costly late-stage redesigns.

Step 3: Root-Cause Analysis — Engineering Insight, Not Just Results

If issues arise, we don’t stop at reporting. ETS engineers work alongside your team to pinpoint the source of EMC problems — whether it’s PCB layout, filtering, shielding, grounding, or cabling. More importantly, we help you engineer practical fixes to move the project forward.

Step 4: Verification Retest — Confidence Before Certification

Once changes are made, we retest to verify the fix. This step provides assurance that the issue is resolved, reducing risk ahead of the final compliance test. It’s about building certainty into your launch plan.

Step 5: Full Compliance Testing — Accredited and Recognised

When your product is ready, we perform full compliance testing under our ISO/IEC 17025 UKAS accreditation. Our results are recognised and accepted for CE, UKCA, and other global market approvals. This is the evidence you need for your Declaration of Conformity and regulatory submission.

Step 6: Reporting and Guidance — Clear, Actionable Documentation

Our reports are designed to be clear, audit-ready, and usable by your regulatory, quality, and design teams. Beyond the paperwork, we provide guidance to help you interpret results and plan next steps for market entry.

Step 7: Long-Term Partnership — Beyond a Single Test

At ETS, we’re more than a test facility—we’re a long-term engineering partner. From early-stage design advisory through to future product updates and retesting, we support your development across product generations. As EMC requirements evolve and your designs advance, we provide the continuity and expertise needed to keep your product compliant, competitive, and ready for market.

Why Choose ETS for EMC Testing?

- UKAS-accredited laboratory with trusted global recognition.

- Hands-on engineering support — we help you solve, not just spot, problems.

- Flexible approach tailored to your design stage and market requirements.

- Trusted reports that streamline approvals for CE, UKCA, and beyond.

Ready to test?

If you’re developing a new product or integrating wireless technologies, engage with ETS early in the process. Together, we’ll ensure that EMC is not an obstacle, but a validated and strategic step on the path to successful market entry.

📧 Contact us | 🌐 www.etsemc.co.uk

Back